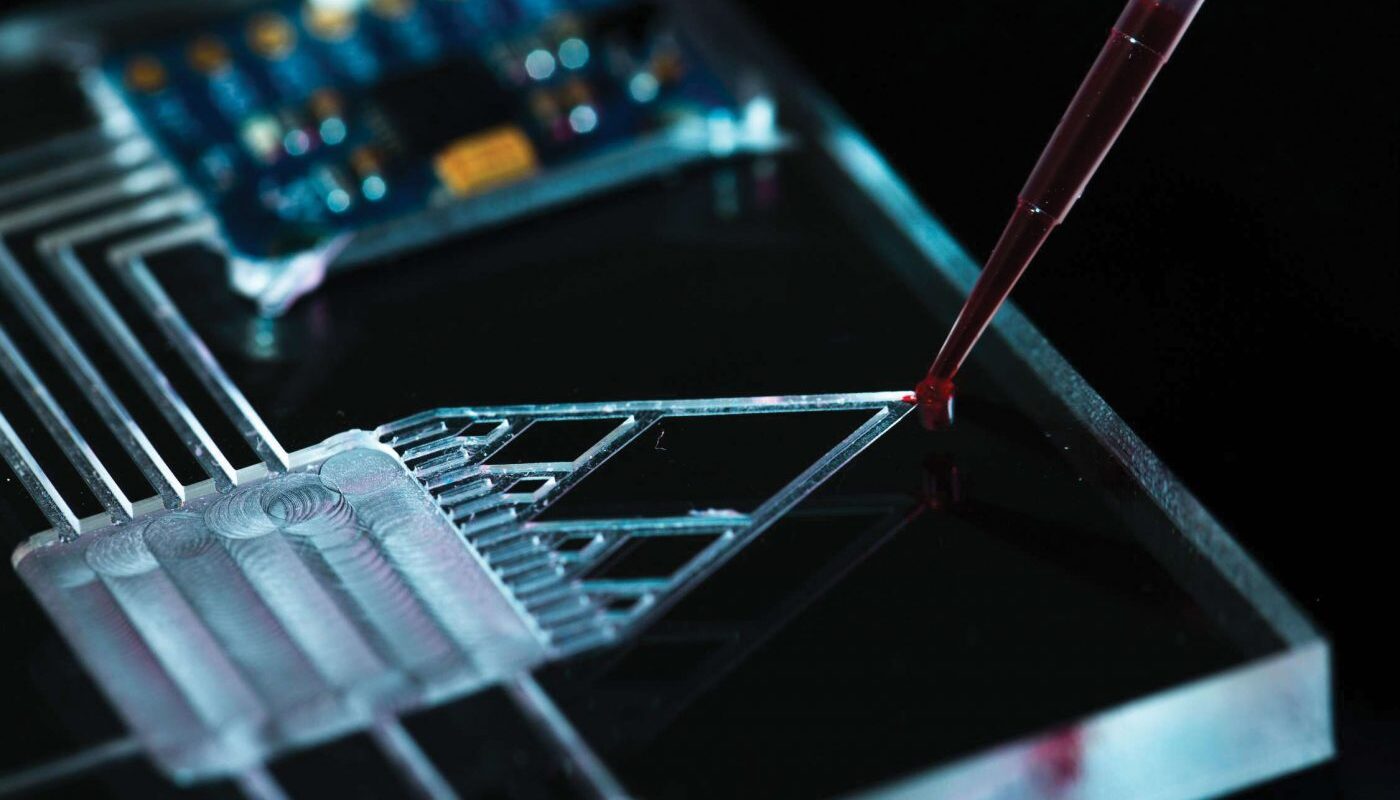

Microfluidic, also known as lab-on-a-chip technology, refers to the science and technology of systems that process or manipulate small amounts of fluids, typically on the scale of microliters or fewer, using channels with dimensions of tens to hundreds of micrometers. Over the past few decades, Microfluidic has emerged as a key enabling technology with applications across various fields including biomedical research, diagnostics, pharmaceutical research and development, environmental monitoring and more.

What is Microfluidic?

As the name suggests, Microfluidic deals with handling and manipulating small amounts of fluids constrained in microscale geometries. The key attributes that define microfluidic systems are reduced spatial dimensions and volumes of fluids. Microfluidic leverages the unique properties that arise when continuing to miniaturize functional elements and integrating them together. Microfluidic devices usually contain a network of microscale channels etched or molded into a substrate material like glass, silicon or polymers.

These channels allow precise control and manipulation of fluids that are pushed or pulled through using various actuation mechanisms like external pressure sources, electrokinetics or integrated micropumps. By taking advantage of laminar flow behavior at microscales and surface tension effects, microfluidic systems can precisely control fluids with unprecedented precision. Microfluidic devices can serve as self-contained, portable “labs-on-a-chip” that perform complex multi-step assays and analytical tests that traditionally required large benchtop instruments.

Enabling Technologies

Over the last few decades, advancements in microfabrication technologies like soft lithography, etching, 3D printing and assembly techniques have enabled rapid prototyping and manufacturing of Microfluidic devices. Materials like silicon, glass and polymers are commonly used to fabricate microfluidic device substrates. Key enabling technologies that have propelled Microfluidic include:

– Photolithography: Standard photolithographic processes adapted from microelectronics allow precise patterning of microscale features on substrates.

– Soft lithography: Techniques like rapid prototyping of microfluidic designs using elastomeric polymers like poly(dimethylsiloxane) (PDMS) have greatly expanded the applications of Microfluidic.

– 3D Printing: Emerging 3D printing methods offer new possibilities for fabricating complex multi-layer microfluidic devices with integrated components.

– Microfabrication: Etching, molding, embossing and bonding methods help fabricate enclosed microfluidic networks and integrate various components.

– Actuation: Integrated micropumps, valves and interfaces for pressure/voltage sources help automate fluid handling in miniaturized devices.

Applications of Microfluidic

The unique attributes of Microfluidic has enabled numerous applications across various domains:

Biomedical Applications

– Lab-on-a-chip devices for point-of-care diagnostics, biomedical assays and experiments have found wide use. Portable microfluidic devices can detect biomarkers from minute sample volumes for applications like disease diagnostics, blood analysis, pathogen detection and more.

– Organ-on-a-chip microfluidic platforms facilitate tissue engineering and replicate complex human physiology for drug development and toxicity screening.

– Microfluidic cell sorting chips enable high-throughput single-cell analysis which has transformed modern biology research.

Pharmaceutical Research and Development

– Microfluidic platforms accelerate drug discovery by enabling high-throughput screening of drug candidates.

– Synthesis of biomolecules, nanoparticles and complex formulations can be done continuously at microscale.

– Microfluidic mixers and reaction chambers facilitate automated microscale experimentation.

Environmental Monitoring

– Lab-on-a-chip devices and portable sensors based on Microfluidic help monitor water quality, detect pollutants and carry out environmental assays on-site.

Food Safety Testing

– Pathogen detection kits based on microfluidic immunoassays help monitor food safety in the supply chain and during processing.

*Note:

1. Source: Coherent Market Insights, Public sources, Desk research

2. We have leveraged AI tools to mine information and compile it