There are a few main types of mask tapes available for different uses. The most common are:

– Paper Masking Tape: Made from paper backing, this type is good for light-duty tasks where a clean edge is desired but not critical. It can tear or shred more easily than other tapes.

– Multi-Purpose Masking Tape: Slightly thicker than paper tape, multi-purpose tape has a slight adhesive that protects surfaces without leaving residue. It works well for masking off areas before painting or for temporary signs.

– Fine-Line Masking Tape: As the name suggests, this Masking Tapes leaves a very thin edgeless line. It’s perfect for detailed work where accuracy is important, like stripping or graphics application. The adhesive is formulated to leave no residue.

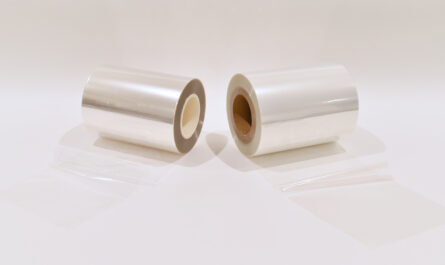

– Foam Masking Tape: With a soft foam backing, this type creates a bubble-free edge. It’s great for glass, metal, and other non-porous surfaces. The foam conforms well without damage.

Choosing the Right Tape for the Job

Knowing which tape to use makes all the difference in your project results. Consider these factors when selecting:

– Surface texture: Smooth surfaces do best with fine-line or foam tapes while porous items work with multi-purpose Masking Tapes.

– Adhesive strength: Light-duty jobs use paper or multi-purpose tape. Foam tape grips well without damage.

– Edge quality: Fine details need fine-line tape. Glass and non-porous materials call for foam tape’s bubble-free edges.

– Project duration: Temporary uses suit paper or multi-purpose tape. Foam stands up to weathering longer.

– Budget: Paper is most affordable but extra applications may be needed. Foam gives value through re-positionability.

Masking Techniques for Perfect Results

Take time to mask areas correctly for the cleanest finished product:

– Remove dust/debris from the surface before applying tape for best adhesion.

– Use smooth, firm pressure as you apply the tape to get full contact without bubbles.

– For straight edges, butt tape ends together with no gaps. For curves, overlap slightly.

– Reposition as needed before painting to ensure a crisp line. Foam tape allows multiple positioning.

– Remove while still wet for the cleanest edge removal without residue. Go slowly to avoid rips.

– For dry paint, use a sharp utility knife to cut the paint at the edge before lifting tape.

Common Uses for Masking Tapes

Whether decorating, crafting, or working on cars and homes, mask tapes make many tasks easier:

– Painting and wallpapering – Mask off trim work, electrical outlets, and other areas to keep paint off.

– Graphic application – Use fine-line tape for logos, letters, and thin vinyl designs on vehicles and signs.

– Stenciling – Mask off areas you don’t want painted by placing tape under stencils.

– Auto repair – Restore pinstriping or paint sections like bumpers without full disassembly.

– Ceramic and glass work – Apply tape as a resist before decorating, etching, or stripping glazes.

– Woodworking – Temporarily hold items in place or mask off sections before finishing.

– Crafts – Assemble composite artworks or test arrangements quickly with repositionable tape.

With so many versatile uses, masking tape should have a permanent home in any toolbox or craft room. For crisp, precise results on any project, proper tape selection and application techniques mean beautiful finishes every time.

*Note:

1. Source: Coherent Market Insights, Public sources, Desk research

2. We have leveraged AI tools to mine information and compile it