Magnesium is the lightest structural metal and has a hexagonal close-packed crystalline structure. With a density of 1.74 g/cm3, magnesium is lighter than aluminum, zinc, and other commonly used metals. It has a melting point of 650°C and a boiling point of 1090°C. Magnesium is silver-white in color and has a shiny appearance when freshly cut or melted.

Some key physical properties of magnesium include its lightweight yet high specific strength. It has a strength to weight ratio better than aluminum and titanium alloys. Magnesium has good heat and electrical conductivity, reflecting over 60% of infrared radiation. It is highly flammable and burns with a characteristic bright white light when ignited.

Chemical Properties and Reactivity

Magnesium Metal reacts readily with oxygen, water, and acids to form oxides, hydroxides, and salts. Finely divided magnesium powder bursts into flames on contact with air due to its high reactivity. When burned in air, magnesium forms magnesium oxide (MgO). Magnesium does not react with pure water but reacts slowly with steam to form magnesium hydroxide.

In the presence of acids, magnesium liberates hydrogen gas. Dilute sulfuric acid does not react readily with magnesium but concentrated sulfuric acid causes immediate evolution of hydrogen. Hydrochloric and nitric acids rapidly corrode magnesium due to formation of magnesium chloride and magnesium nitrate respectively. Molten salts like NaCl and KCl dissolve magnesium readily due to formation of relatively stable magnesium chlorides.

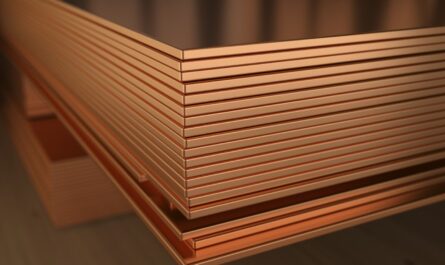

Alloying and Applications

Magnesium Metal is rarely used in its pure form due to poor mechanical properties and corrosion resistance. Alloying magnesium with other metals significantly improves its properties for structural applications. Common alloying elements include aluminum, zinc, manganese, and rare earth metals.

Aluminum-magnesium alloys like AZ91D contain up to 9% aluminum and 1% zinc. These have excellent castability and corrosion resistance. Zinc-magnesium alloys containing up to 5% zinc are used for die casting auto parts. Magnesium alloys containing 6-10% aluminum and 1-3% manganese like AM50 and AM60 have good strength and machinability for aerospace components.

Some key application areas of magnesium alloys include automotive, aerospace, electronics, and construction industries:

– Automotive components: Transmission casings, steering wheels, seat frames, braking systems.

– Aerospace structures: Aircraft seats, instrument panels, casing covers.

– Electronics: Housings for laptops, smartphones, cameras due to good castability and electromagnetic shielding.

– Construction: Decking, fencing, windows due to fire resistance and lightweight profiled structures.

Green Manufacturing of Magnesium

Due to the reactive nature of magnesium metal, traditional powder metallurgy or ingot casting routes require energy intensive remelting under protective atmospheres like dry air or ammonia. However, green manufacturing methods like molten salt electrowinning are being developed to directly extract pure magnesium from seawater or magnesite minerals.

In molten salt electrowinning, magnesium chloride salts dissolved in a molten salt electrolyte like KCl-MgCl2 are electrolyzed in an inert carbon lined cell. Applying a DC voltage causes pure magnesium to deposit at the cathode while chlorine gas evolves at the anode. This method avoids multiple energy intensive melting steps and produces magnesium with low carbon footprint. The molten salt acts as a thermal energy storage medium and can be recycled for further electrolysis.

Research is ongoing to develop higher voltage electrolysis cells to reduce electricity costs. Efforts are also underway to integrate molten salt magnesium electrolysis with renewable solar, wind or nuclear energy for truly green primary magnesium production. These developments promise to make magnesium extraction more sustainable and economically viable on an industrial scale.

Magnesium possesses a unique combination of properties making it an ideal light structural metal for applications across many industries. With ongoing advancements in alloy development and green manufacturing methods, magnesium usage is forecast to grow substantially in the coming years.

*Note:

1. Source: Coherent Market Insights, Public sources, Desk research

2. We have leveraged AI tools to mine information and compile it

About Author:

Money Singh is a seasoned content writer with over four years of experience in the market research sector. Her expertise spans various industries, including food and beverages, biotechnology, chemical and materials, defense and aerospace, consumer goods, etc. (https://www.linkedin.com/in/money-singh-590844163)