The global Micro Molding Materials Market is estimated to be valued at US$ 1.27 Bn in 2023 and is expected to exhibit a CAGR of 11% over the forecast period 2023 to 2030, as highlighted in a new report published by Coherent Market Insights.

Market Overview:

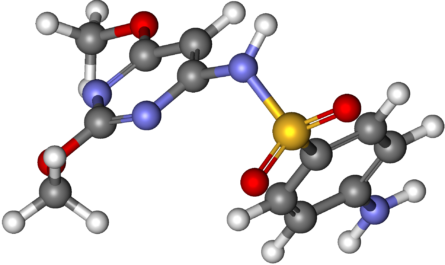

Micro molding involves molding of materials into very small components that have complex geometries and tight tolerances. Micro molding materials are widely used in manufacturing tiny parts and components that find application across various industries such as automotive, healthcare, consumer electronics, and telecommunications. These materials aid in manufacturing miniature and precision parts with intricate three-dimensional features. Micro molding helps produce complex plastic components in high volumes with excellent dimensional accuracy and surface finish. The key materials used for micro molding include liquid crystal polymers, polyamide, polyoxymethylene, liquid silicone rubber, polycarbonate, and polyetherimide. Compared to conventional molding techniques, micro molding offers advantages such as reduced part weight, tighter tolerances, complex geometries, and enhanced structural integrity. Growing demand for miniature parts from end-use industries is driving the micro molding materials market.

Market key trends:

One of the major trends gaining traction in the micro molding materials market is the increasing adoption of liquid injection molding (LIM) technology. LIM technology involves molding liquid silicone rubber or thermoplastic elastomers in micro mold cavities using precise injection methods. It allows manufacturing of soft, intricate rubber parts with complex geometries and feature sizes as small as 50-100 microns. This technology is widely utilized in manufacturing medical devices and electronics components. Growing usage of LIM in biomedical devices manufacturing is expected to push the demand for LIM compatible micro molding materials. Another significant trend is the rising preference for liquid crystal polymer (LCP) materials in micro molding. LCP materials offer properties such as dimensional stability, chemical resistance, and high melting points. Hence, they are highly suitable for precision micro molding applications. Increasing R&D into developing new grades of LCP suitable for micro-scale molding is slated to drive their usage.

Porter’s Analysis

Threat of new entrants: Low capital requirements and technological expertise pose a low threat of new entrants in the micro molding materials market.

Bargaining power of buyers: Large buyers have significant bargaining power over micro molding materials suppliers due to the substitutable and price sensitive nature of the products.

Bargaining power of suppliers: Suppliers have moderate bargaining power due to the availability of substitute materials in the market.

Threat of new substitutes: New substitutes pose a moderate threat as they require significant R&D investments and time to penetrate the market.

Competitive rivalry: The competitive rivalry in the micro molding materials market is high due to presence of numerous global and regional players.

Key Takeaways

The global micro molding materials market is expected to witness high growth, exhibiting CAGR of 11% over the forecast period, due to increasing demand from healthcare sector. Micro molding finds extensive usage in manufacturing miniature medical devices like surgical tools, implants etc.

Regional analysis: Asia Pacific dominates the global micro molding materials market and is expected to grow at the fastest pace during the forecast period. Continuous expansion of small component manufacturing industries like automotive, electronics etc in China and India is driving the regional market.

Key players operating in the micro molding materials market are Precimold Inc., Accumold, Micromold Inc., Stack Plastics, American Precision Products, ALC Precision, Micromolding Solutions, Micro Precision Products, American Precision Products, Stamm, Makuta Technics, Sovrin Plastics, Rolla AG, and Rapidwerks. Accumold and Micromold Inc. have the largest market share in the global market.